The Design to Fab Process

Every piece begins with a spark of inspiration and ends with craftsmanship you can see and feel. From concept and design through to laser cutting and finishing, each creation is shaped with care in our regional NSW workshop.

Our process ensures precision, quality, and a smooth journey from your initial inspiration to the finished product.

Concept to CAD

Every custom sign, product, or project begins with transforming your vision into a language our machines can understand. From the moment your enquiry arrives—whether it includes a rough sketch, logo file, or simply an idea—we refine your concept for both aesthetic balance and structural integrity.

Next, the artwork is carefully built in CAD (Computer-Aided Design). This is where creativity meets technical precision. Each element is adjusted for scale, stability, and flow before being meticulously “nested” within our cutting software. This critical step optimises cutting paths, spacing, and kerning (the letter spacing between characters) to ensure every cut is clean, efficient, and true to your design.

Laser Cutting, Fabrication & Finishing

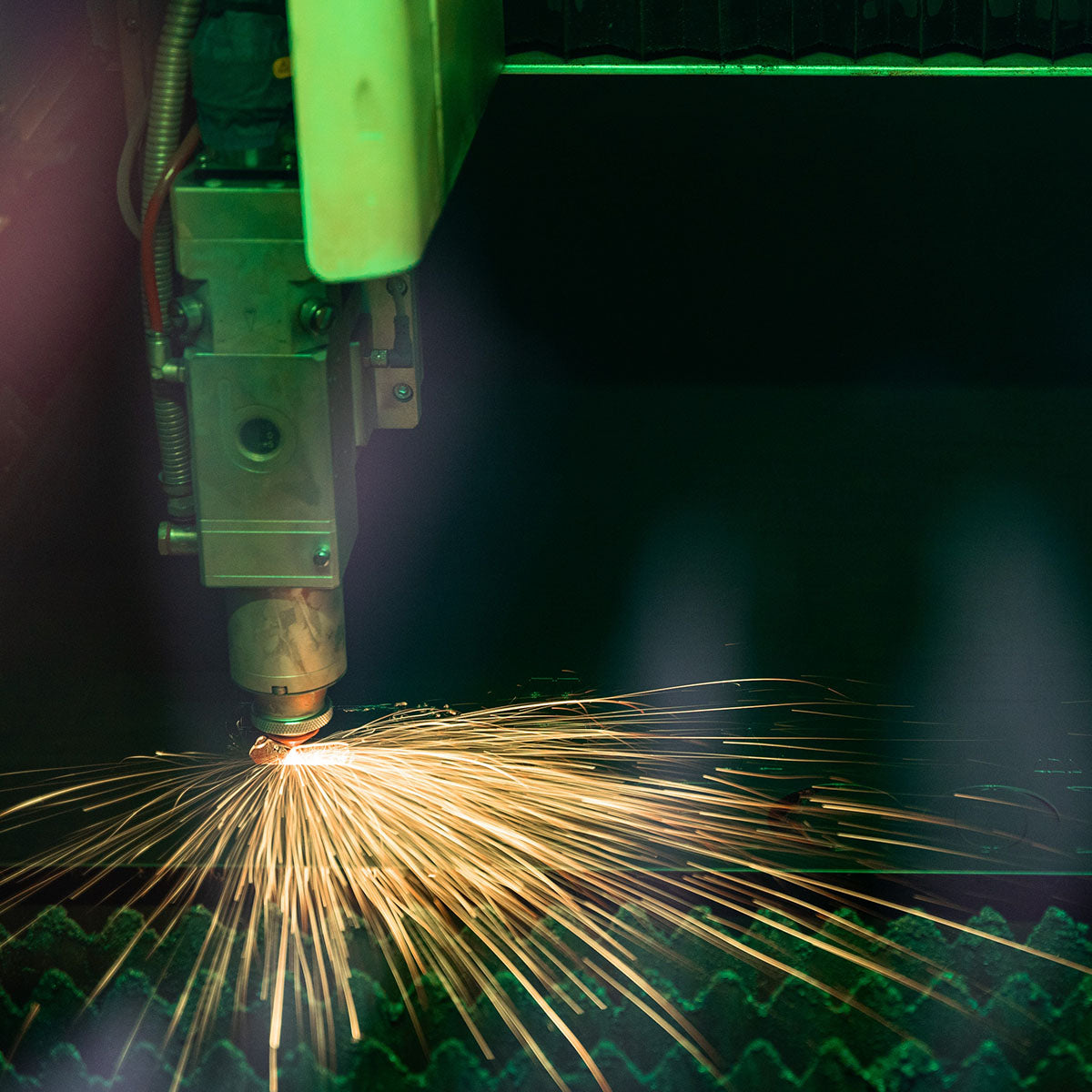

This is where accuracy guarantees quality. Using the specified metal type and thickness, your design is laser cut with precision equipment that delivers crisp, consistent detail every time.

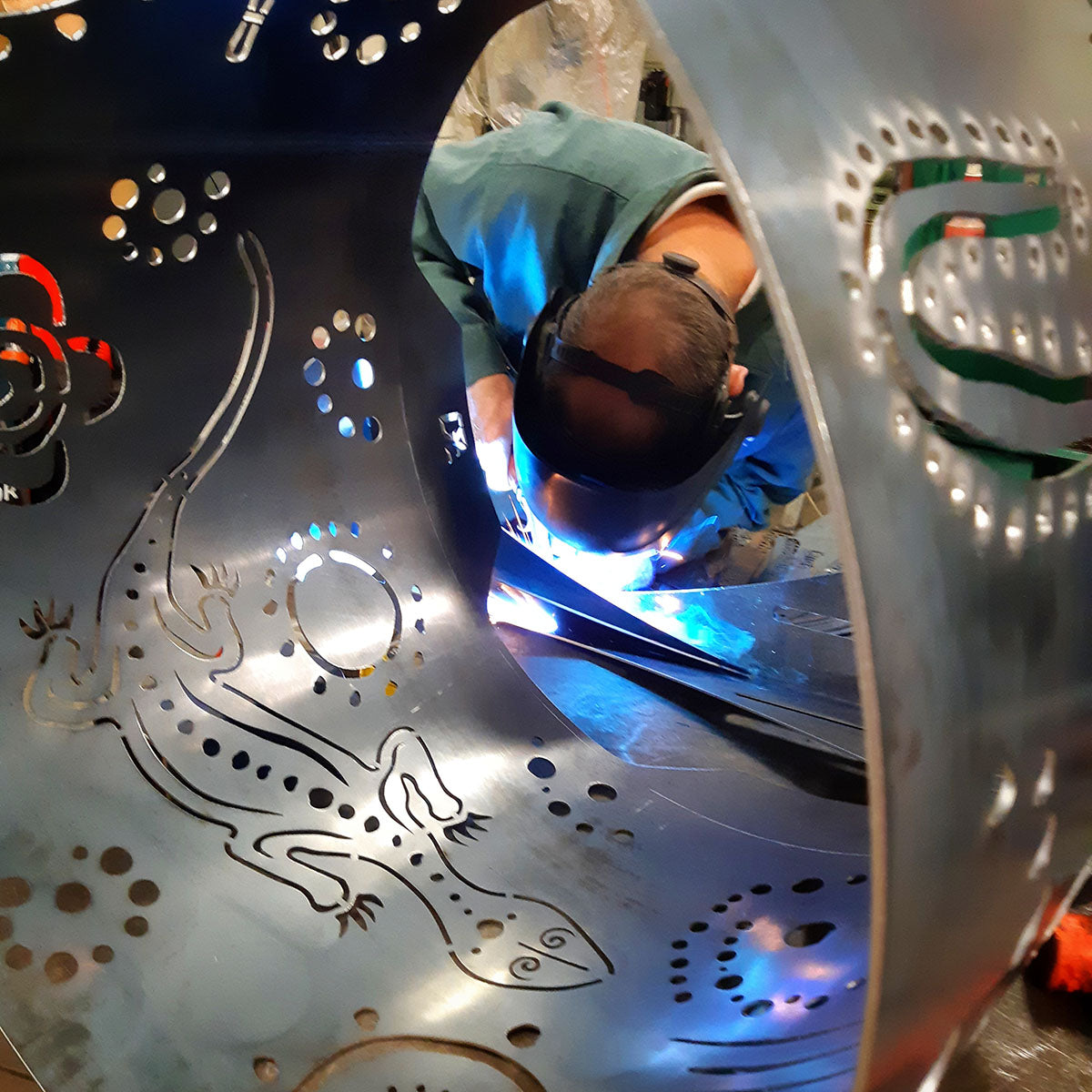

For projects beyond flat signs, this is where Jason’s fabrication expertise comes to life — shaping, assembling, and refining each piece with care. Edges are cleaned, details checked, and finishes applied to ensure the end result not only looks stunning but is built to last.

Laser Cutting Capabilities

At the heart of our workshop is our Bodor 3kW fibre laser cutter - the machine that brings precision and creativity together. This advanced technology allows us to produce exceptionally clean cuts, fine details, and consistent results across a diverse range of materials and thicknesses.

By keeping our laser cutting capability in-house, we maintain complete control over both quality and scheduling, ensuring every project meets our exacting standards from start to finish. The result is accuracy you can see - sharp edges, smooth finishes, and perfectly cut designs ready for fabrication or finishing.

Whether we’re producing a single custom garden sign or precision components for a larger fabrication project, our equipment and expertise ensure every piece is made to the highest standard.

Materials

We laser cut and fabricate from a wide range of steel materials to suit different applications, aesthetics, and environments. We don’t cut timber, acrylic, copper or brass.

Our material range includes

- Mild Steel – up to 20mm thick. Strong, versatile, and suitable for most fabrication applications. Also for powder-coated or painted colour finish.

- Stainless Steel – up to 10mm thick. Sleek, durable, and highly resistant to corrosion. Perfect for long-lasting decorative features and modern accents, particularly in coastal or high-moisture environments.

- Aluminium – up to 10mm thick. Lightweight yet strong, offering a clean modern finish.

- Weathering Steel – develops a rich, natural rust patina that protects the metal while adding a beautiful rustic character.

- Galvanised & Zincanneal Steel – coated for corrosion resistance, offering durability and a uniform surface finish.

Every material is selected to suit the design’s purpose and environment - whether it’s a statement garden piece, workshop sign, or precision component.

Crafted with Soul

Every piece that leaves our workshop reflects the same care, creativity, and craftsmanship that define everything we make.

Inspired by nature – crafted with soul, each design is created to endure the elements and bring lasting character to your space.

To keep your piece looking its best over time, visit our Product Care page for simple care and maintenance tips.